Your location??Home > Technical > NdFeB magnet/span>

|

|

|

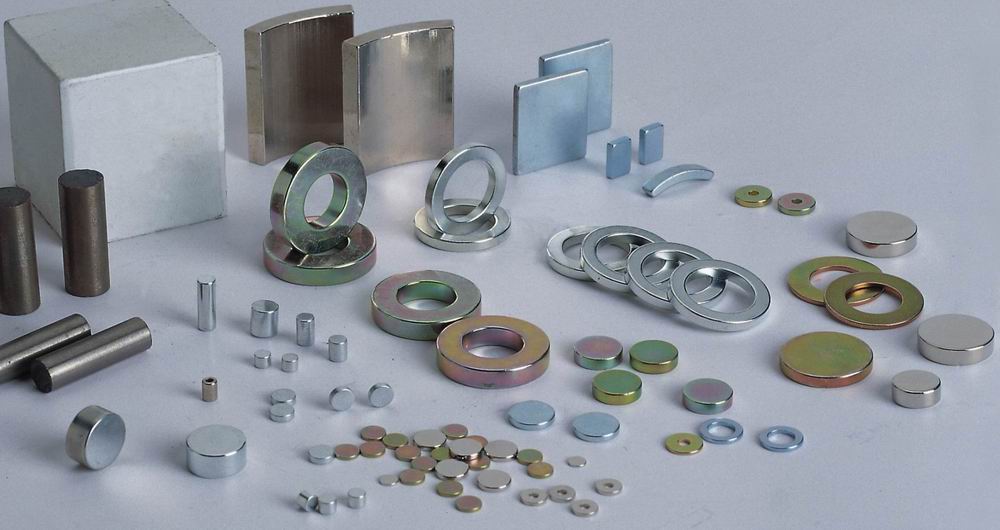

NEODYMIUM-IRON-BORON MAGNETS (Rare earth permanent magnetic).

Sintered neodymium-iron-boron (NdFeB) magnets, They

offer the highest energy product of any material today and are

available in a very wide range of shapes, sizes and

grades.

MAXIMUM USE TEMPERATURE AND CORROSION

The

temperature stability and resist corrosion is not as good as

permanent ferrite magnet.

THE

CHARACTERISTICSSTANDARDS.

|

???

Grade |

???

Remanence induction |

??????

Coercive force |

??????????

Intrinsic Coercive force

|

???????

maximum Energy product |

???????

Temperature |

???

Density |

|

Br |

Hcb |

Hcj |

(BH)max |

Pc??0.7 |

?? |

|

T |

KGs |

KA/m |

KOe |

KA/m |

KOe |

KJ/m3 |

MGOe |

?? |

g/cm3 |

|

N33 |

1.14-1.17 |

11.4-11.7 |

??836 |

??10.5 |

??955 |

??12 |

247-263 |

31-33 |

??80 |

??7.4 |

|

N35 |

1.17-1.22 |

11.7-12.2 |

??859 |

??10.8 |

??955 |

??12 |

263-287 |

33-36 |

??80 |

??7.4 |

|

N38 |

1.22-1.26 |

12.2-12.6 |

??859 |

??10.8 |

??955 |

??12 |

287-303 |

36-38 |

??80 |

??7.5 |

|

N40 |

1.26-1.29 |

12.6-12.9 |

??836 |

??10.5 |

??955 |

??12 |

303-318 |

38-40 |

??80 |

??7.5 |

|

N42 |

1.29-1.32 |

12.9-13.2 |

??836 |

??10.5 |

??955 |

??12 |

318-342 |

40-43 |

??80 |

??7.5 |

|

N45 |

1.32-1.37 |

13.2-13.7 |

??836 |

??10.5 |

??955 |

??12 |

342-359 |

43-45 |

??80 |

??7.5 |

|

N48 |

1.36-1.42 |

13.6-14.2 |

??836 |

??10.5 |

??955 |

??12 |

358-382 |

45-49 |

??80 |

??7.5 |

|

N50 |

1.40-1.45 |

14.0-14.5 |

??836 |

??10.5 |

??955 |

??12 |

374-406 |

47-51 |

??80 |

??7.5 |

|

N52 |

1.42-1.48 |

14.2-14.8 |

??836 |

??10.5 |

??876 |

??11 |

389-422 |

49-53 |

??80 |

??7.5 |

|

N30M |

1.08-1.14 |

10.8-11.4 |

??812 |

??10.2 |

??1114 |

??14 |

223-247 |

28-31 |

??100 |

??7.5 |

|

N33M |

1.14-1.17 |

11.4-11.7 |

??852 |

??10.7 |

??1114 |

??14 |

247-263 |

31-33 |

??100 |

??7.5 |

|

N35M |

1.17-1.22 |

11.7-12.2 |

??876 |

??11.0 |

??1114 |

??14 |

263-287 |

33-36 |

??100 |

??7.5 |

|

N38M |

1.22-1.26 |

12.2-12.6 |

??916 |

??11.5 |

??1114 |

??14 |

287-303 |

36-38 |

??100 |

??7.5 |

|

N40M |

1.26-1.29 |

12.6-12.9 |

??939 |

??11.8 |

??1114 |

??14 |

303-318 |

38-40 |

??100 |

??7.5 |

|

N42M |

1.29-1.32 |

12.9-13.2 |

??955 |

??12.0 |

??1114 |

??14 |

318-334 |

40-42 |

??100 |

??7.5 |

|

N45M |

1.32-1.38 |

13.2-13.8 |

??987 |

??12.4 |

??1114 |

??14 |

334-366 |

42-46 |

??100 |

??7.5 |

|

N48M |

1.36-1.42 |

13.6-14.2 |

??1018 |

??12.8 |

??1114 |

??14 |

358-390 |

45-49 |

??100 |

??7.5 |

|

N50M |

1.39-1.45 |

13.9-14.5 |

??1050 |

??13.2 |

??1114 |

??14 |

374-406 |

47-51 |

??100 |

??7.5 |

|

N30H |

1.08-1.14 |

10.8-11.4 |

??812 |

??10.2 |

??1353 |

??17 |

223-247 |

28-31 |

??120 |

??7.5 |

|

N33H |

1.14-1.17 |

11.4-11.7 |

??851 |

??10.7 |

??1353 |

??17 |

247-263 |

31-33 |

??120 |

??7.5 |

|

N35H |

1.17-1.22 |

11.7-12.2 |

??875 |

??11.0 |

??1353 |

??17 |

263-287 |

33-36 |

??120 |

??7.5 |

|

N38H |

1.22-1.26 |

12.2-12.6 |

??916 |

??11.6 |

??1353 |

??17 |

287-303 |

36-38 |

??120 |

??7.5 |

|

N40H |

1.26-1.29 |

12.6-12.9 |

??939 |

??11.8 |

??1353 |

??17 |

303-318 |

38-40 |

??120 |

??7.5 |

|

N42H |

1.29-1.32 |

12.9-13.2 |

??955 |

??12.0 |

??1353 |

??17 |

318-334 |

40-42 |

??120 |

??7.5 |

|

N45H |

1.32-1.38 |

13.2-13.8 |

??987 |

??12.4 |

??1353 |

??17 |

334-366 |

42-46 |

??120 |

??7.5 |

|

N48H |

1.36-1.42 |

13.6-14.2 |

??1026 |

??12.9 |

??1273 |

??16 |

358-390 |

45-49 |

??120 |

??7.5 |

|

N30SH |

1.08-1.14 |

10.8-11.4 |

??812 |

??10.2 |

??1592 |

??20 |

223-247 |

28-31 |

??150 |

??7.5 |

|

N33SH |

1.14-1.17 |

11.4-11.7 |

??851 |

??10.7 |

??1592 |

??20 |

247-263 |

31-33 |

??150 |

??7.5 |

|

N35SH |

1.17-1.22 |

11.7-12.2 |

??876 |

??11.0 |

??1592 |

??20 |

263-287 |

33-36 |

??150 |

??7.5 |

|

N38SH |

1.22-1.26 |

12.2-12.6 |

??899 |

??11.3 |

??1592 |

??20 |

287-303 |

36-38 |

??150 |

??7.5 |

|

N40SH |

1.26-1.29 |

12.6-12.9 |

??931 |

??11.7 |

??1592 |

??20 |

303-318 |

38-40 |

??150 |

??7.5 |

|

N42SH |

1.29-1.32 |

12.9-13.2 |

??963 |

??12.1 |

??1592 |

??20 |

318-334 |

40-42 |

??150 |

??7.5 |

|

N44SH |

1.30-1.36 |

13.0-13.6 |

??995 |

??12.3 |

??1592 |

??20 |

326-359 |

41-45 |

??150 |

??7.5 |

|

N30UH |

1.08-1.14 |

10.8-11.4 |

??812 |

??10.2 |

??1990 |

??25 |

223-247 |

28-31 |

??180 |

??7.5 |

|

N33UH |

1.14-1.17 |

11.4-11.7 |

??851 |

??10.7 |

??1990 |

??25 |

247-263 |

31-33 |

??180 |

??7.5 |

|

N35UH |

1.17-1.22 |

11.7-12.2 |

??875 |

??11.0 |

??1990 |

??25 |

263-287 |

33-36 |

??180 |

??7.5 |

|

N38UH |

1.22-1.26 |

12.2-12.6 |

??915 |

??11.5 |

??1990 |

??25 |

287-302 |

36-38 |

??180 |

??7.5 |

|

N40UH |

1.26-1.32 |

12.6-13.2 |

??939 |

??11.8 |

??1990 |

??25 |

302-334 |

38-42 |

??180 |

??7.5 |

|

N30EH |

1.08-1.14 |

10.8-11.4 |

??812 |

??10.2 |

??2388 |

??30 |

223-247 |

28-31 |

??200 |

??7.5 |

|

N33EH |

1.14-1.17 |

11.4-11.7 |

??851 |

??10.7 |

??2388 |

??30 |

247-263 |

31-33 |

??200 |

??7.5 |

|

N35EH |

1.17-1.25 |

11.7-12.5 |

??875 |

??11.0 |

??2388 |

??30 |

263-295 |

33-37 |

??200 |

??7.5 |

|

N38EH |

1.22-1.29 |

12.2-12.9 |

??907 |

??11.4 |

??2388 |

??30 |

287-318 |

36-40 |

??200 |

??7.5 |

|

N30AH |

1.08-1.20 |

10.8-12.0 |

??860 |

??10.8 |

??2626 |

??33 |

247-263 |

31-35 |

??220 |

??7.5 |

|

Remark:

??magnetic conductivity??rec-1.05, Currie Temperature Tc=310??

??The above magnetic parameters and physical features are measured at room temperature. The sample is D10??10 inspection figures.

??The highest service temperature relies on the length width ratio and environmental factors. The magnetic flux is less or equal to 5% at such temperature??

|